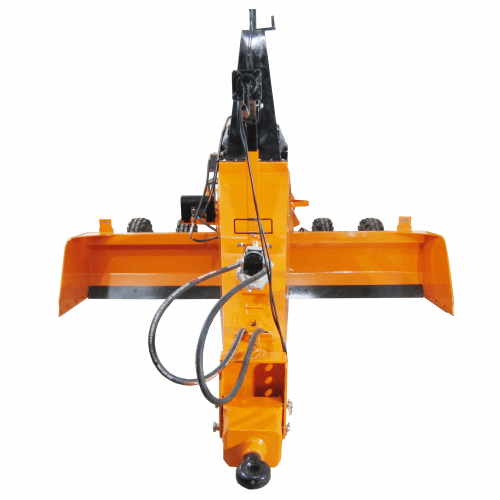

Optimize efficiency with Celec’ Laser Land Leveler Kit Pro-2000. Enjoy self-leveling, long-range precision, Windy function, and Cross-Axis Compensation for superior agricultural performance.

Celec Group leads the agricultural technology revolution with its pioneering laser leveler technology tailored for Indian farmers. Developed, tested, and manufactured at our Ludhiana Plant, our laser leveler stands out for its exceptional performance and durability in the field.

The Pro 2000 Laser Leveler Kit is a comprehensive solution designed to elevate farming operations. It includes the Celec Pro 2000 Laser, Touch Control Box, Laser Receiver, IR Remote, Control Box Remote, and cables for seamless integration and control.

Key Features of the Pro 2000 Laser Leveler Kit:

Impressive Operating Range: With a reach of 1000 meters (500-meter radius), Celec laser leveler ensures extensive coverage for agricultural tasks.

Precision Self-Leveling: Achieving ±1 mm accuracy at 30 meters, our technology guarantees precise results for every task.

Extended Battery Life: With a robust battery offering up to 72 hours of runtime, farmers can rely on uninterrupted operation during critical tasks.

Rugged Design: IP65-rated dust and water resistance ensure durability and reliability in harsh agricultural environments.

Wide Temperature Range: Operating flawlessly from 0 to 50°C, our laser leveler adapts to varying weather conditions for consistent performance.

Celec is committed to delivering superior quality products that empower farmers to excel. With our laser leveler technology, we provide the tools needed to navigate the challenges of modern agriculture effectively.

424 364 2640

424 364 2640